Selecting the correct extruder screen pack is crucial for achieving optimal filtration, maintaining consistent pressure, and ensuring production efficiency. The choice depends on several key factors, primarily the polymer type, contamination level, and the specific extrusion process requirements.

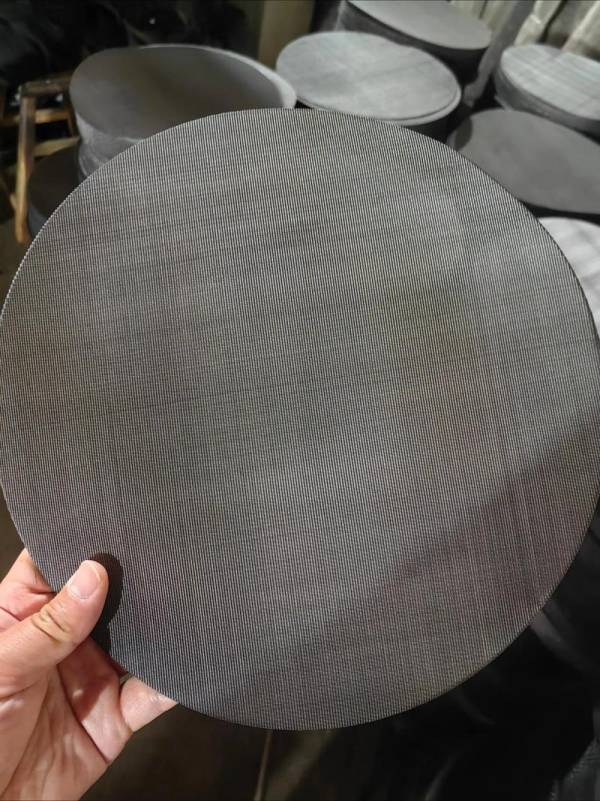

The most critical consideration is filtration fineness, determined by the mesh count. A higher mesh number (e.g., 200 or finer) removes smaller contaminants but causes a faster pressure increase. A common and effective strategy is to use a layered, or “staged,” pack. This typically involves placing coarser screens (e.g., 20-40 mesh) on the sides to support finer screens (e.g., 60-150 mesh) in the middle. This graded structure traps particles efficiently while providing structural support and extending screen life.

Material compatibility is another vital factor. For standard polymers like polyolefins, standard stainless-steel screens are sufficient. However, for highly corrosive materials (e.g., PVC, fluoropolymers), screens made from specialized stainless steels like 316 or even nickel-based alloys are necessary to prevent premature failure.

Finally, the choice between manual and automatic screen changers dictates screen type. Continuous processes using automatic screen changers require robust, uniformly packed screens, often in cartridge form, designed to withstand continuous pressure. For manual systems, cost-effective layered packs are standard. Ultimately, the ideal screen pack balances contaminant removal with acceptable pressure buildup and operational cost.