Professional Extruder Screen Suppliers in the USA

All Regions of the USA, Door-to-Door Delivery

Introduction to Extruder Screens (Screen Packs)

An extruder screen, or screen pack, is a critical component in the plastic extrusion process. It is a layered assembly of woven wire mesh screens placed in the path of the molten polymer, just before it reaches the die.

Primary Functions:

Filtration and Contaminant Removal: This is its core purpose. The screen traps foreign particles such as dirt, carbonized material, gel particles, and un-melted polymer resin. This purification step is essential for producing extruded products with consistent quality and a clean surface finish.

Improving Melt Homogeneity: As the molten plastic is forced through the fine mesh, it experiences a mixing and shearing action. This helps to break up any remaining polymer agglomerates and creates a more uniform melt temperature and viscosity, leading to a more consistent product dimension.

Backpressure Generation: The screen creates a controlled resistance to the flow of the polymer. This increased backpressure is beneficial as it improves the mixing efficiency of the extruder screw, resulting in better melting and devolatilization (removal of entrapped air/gases).

Equipment Protection: By filtering out hard contaminants, the screen pack acts as a final barrier, protecting the expensive and precision-machined extrusion die from abrasion and potential clogging.

Construction and Selection:

Materials:

Screens are typically made from durable, corrosion-resistant metals like stainless steel.

Mesh Configuration (Screen Pack):

Screens are used in a "pack" with different mesh sizes layered together. A common arrangement is a coarse screen on the outside for support, with progressively finer screens in the middle.

Mesh Count:

Measured in microns or "mesh" (openings per inch). A higher mesh number means smaller openings and finer filtration.

Single Screen Filters/Spot Welded Filter Packs/Rimmed Mesh Filters

Your Most Trusted Extrusion Filtration Expert

In the plastics, rubber, and chemical extrusion industries, the purity and homogeneity of the melt directly determine the quality of the final product, production efficiency, and operational costs. HM is deeply engaged in the R&D and manufacturing of Extruder Screens, committed to providing global clients with efficient, reliable, and customized filtration solutions, becoming an indispensable and loyal partner on your production line.

Our Core Advantages:

Precise & Scientific Screen Pack Design

We are not just a manufacturer but also your technical consultant. Our engineering team designs multi-layer screen pack combinations (e.g., 20/40/60/20 Mesh) based on your specific raw material characteristics (such as PVC, PE, PP, engineering plastics), product requirements, and extruder model.

Benefit: Achieves the optimal balance between contaminant removal and melt pressure, significantly enhancing product surface finish and dimensional stability, while preventing production loss caused by improper backpressure.

Superior & Durable Materials & Craftsmanship

We strictly select high-grade stainless steels (e.g., 304, 316, 316L) and special alloys, ensuring our screens possess excellent heat resistance, corrosion resistance, and anti-creep properties.

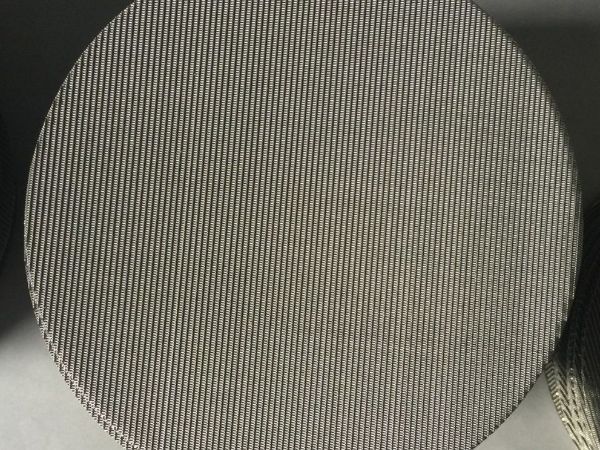

Utilizing precision weaving technology, we guarantee uniform mesh openings and accurate wire diameter. This provides consistent filtration accuracy while withstanding extreme extrusion pressure, effectively extending screen service life.

Tailored for Automatic Screen Changers

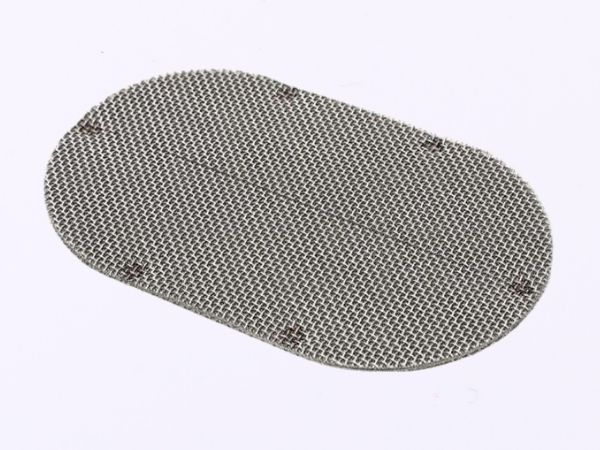

We deeply understand the value of continuous production. Our screens are specifically designed for various Automatic Screen Changers, featuring high mechanical strength and excellent edge sealing.

Benefit: Ensures a smooth, leak-free screen changing process, enabling non-stop production, minimizing waste, and saving you from costly downtime.

Comprehensive Product Matrix & Customization Services

We offer a full range of products from coarse to ultra-fine filtration, covering a wide mesh spectrum to meet diverse demanding needs – from recycled material processing to precision medical tubing production.

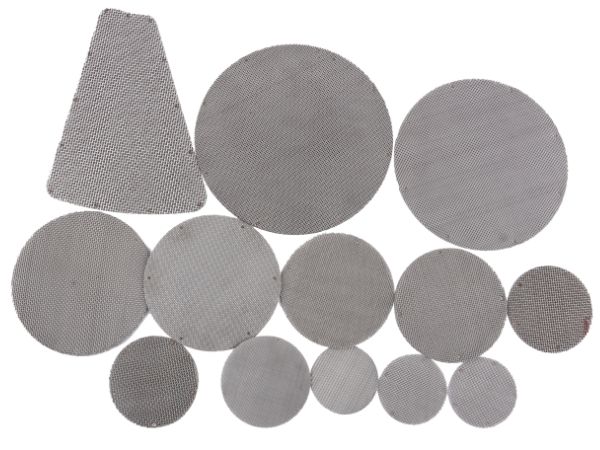

Full Customization Supported: Whether it’s special shapes (Round, Square, Sector), specific dimensions, or special coatings (e.g., non-stick coating), we can deliver.

Why Choose Us?

Deeper Technical Understanding: We understand the extrusion process; our advice can make your production line run more smoothly.

Uncompromising Quality Control: Every single screen undergoes strict inspection from raw material to finished product, ensuring guaranteed performance.

Rapid-Response Service Team: We provide timely technical support and fast delivery cycles to help you meet urgent production needs.

blog

latest

- Your Wyoming Partner for Extruder Screen Packs 3 12 月, 2025

- Your Wisconsin Partner for Extruder Screen Packs 3 12 月, 2025

- Your West Virginia Partner for Extruder Screen Packs 3 12 月, 2025

- Your Washington Partner for Extruder Screen Packs 3 12 月, 2025

- Your Vermont Partner for Extruder Screen Packs 3 12 月, 2025

- Your Trusted Extruder Screen Pack Supplier in Utah 3 12 月, 2025

- Your Trusted Extruder Screen Pack Supplier in Texas 3 12 月, 2025

- Your Reliable Partner for Extruder Screen Packs in Tennessee 3 12 月, 2025

- Your Local Partner for Extruder Screen Packs in South Dakota 3 12 月, 2025

- Your Trusted Source for Extruder Screen Packs in South Carolina 3 12 月, 2025